-

#15

by

rodpaslow

on 02 May, 2014 14:24

-

Read the faq section, I think it's on 2nd page, if you want to stay with VW stuff, you have to do some mods to the control lever as the stroke of the control collar needs to be different than any of the pumps you have.

That is why the rover pumps are so great. The camplate is good for the 11mm head it comes with and the control lever already has longer setup, better adjustment setup, etc. (but the lever is a bit different than the VW, or at least the one I have is)

Changing the contol lever looks pretty involved, with fine welding skills needed, as well as colbalt or carbide drill needed as the control lever is not just mild steel.

As for the AAZ governor, I've read others have used it with okay results with the modified control lever.

I didn't want to have to do any machining to the bracket, so I've basically done what you are thinking. I had a AAZ pump I basically pulled apart and put all the rover bits into it. I will be installing it this weekend to make sure it's going to work; as the housings are basically the same, only it has the longer timing cover, a better camplate and control lever. All seals were replaced doing the swap over as well. I will update if it works fine after this weekend.

-

#16

by

SDTS

on 02 May, 2014 18:04

-

Tonight I took the pumps apart and swapped everything, but I didn't expect a problem with the contol lever, so I'll have to look into that and modify it next week if neccesary, the welding and drilling shouldn't be a problem.

Now I have an AAZ pump, with TDI advance mechanism, TDI camplate and 10mm plunger and pump head. Orther than that nothing changed.

I noticed a few things:

When I had the pumps apart, I notced the TDI has an extra spring pressing against the camplate from the inside the AAZ doesn't have, I hope that won't be a problem.

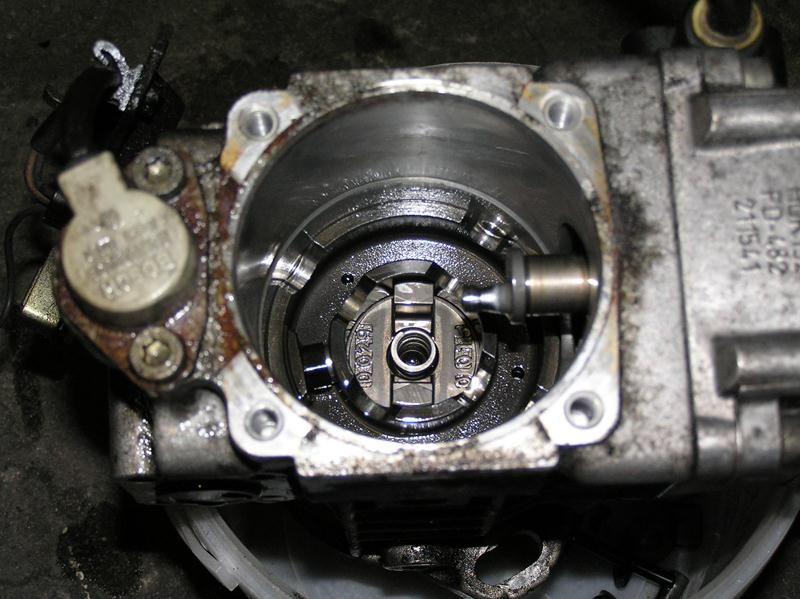

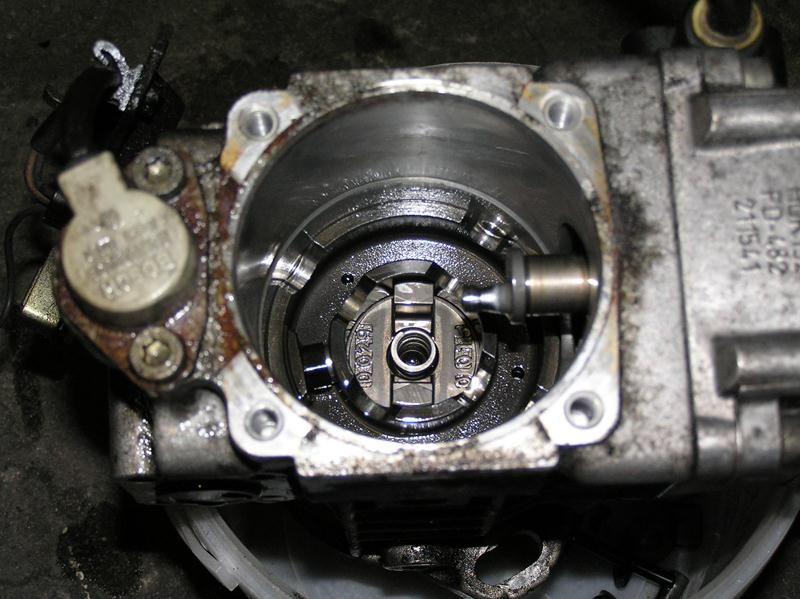

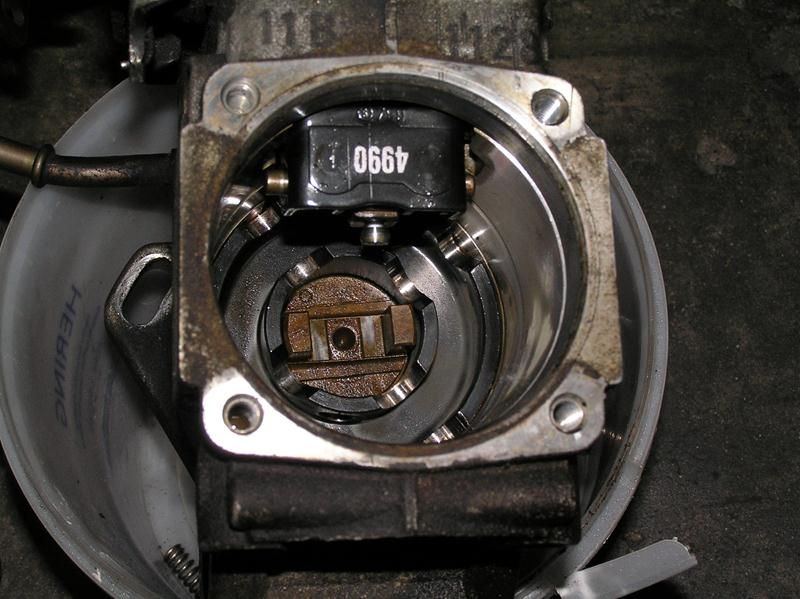

TDI inside:

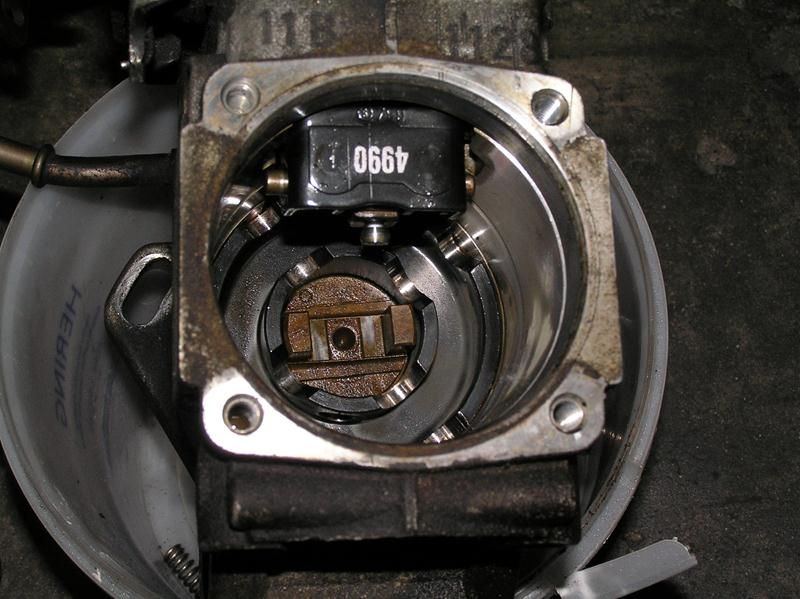

AAZ inside:

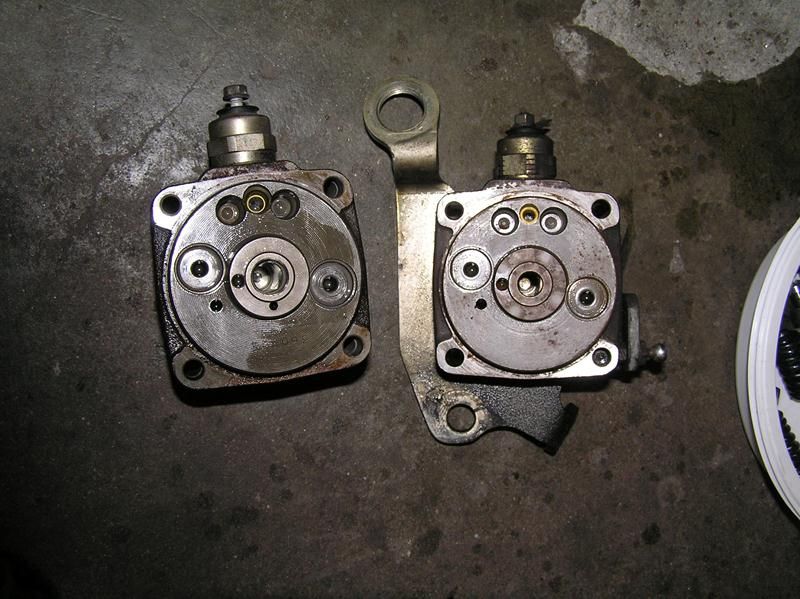

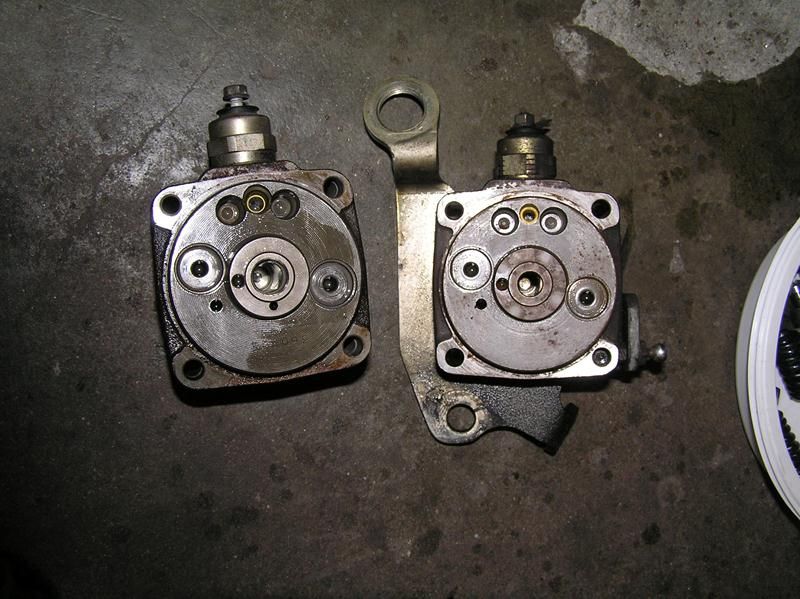

Also, having the pumps apart the differece between camplates is clearly visible:

TDI on the left, AAZ in the middle and 1,6 on the right.

TDI and AAZ both have 3mm lift, 1,6D has 2mm. Also the TDI has a much steeper slope on one side, so the AAZ camplate probably wouldn't have worked.

Luckily the 10mm pump head already had the holes for the conrol lever spring pre drilled, because there are no springs in the tdi pump, so that could have become a problem:

The advance pistons and covers don't appear to differ very much, onlt the spring is different, double for AAZ, and a single, thicker spring in the TDI:

when fitting the assembled pump, it turned out there is little room around the lda because of the fuel lines, but it is just enough for the fuel screw and out banjo fitting:

-

#17

by

SDTS

on 14 May, 2014 07:21

-

This week I finally had the time to swap in the 1Z engine.

At the last minute I decided since I don't use a turbo I would better use the 1y pump instead of the aaz pump, because I know it is in very good condition. So I decided I would only swap the TDI camplate and 10mm head into the 8mm 1y pump, thinking it probably wouldn't work because of different advance mechanism and control lever, but giving it a try anyway. To my surpise it fired right up at the first try and idled very smooth, without adjusting anything. Then I went for a test drive and it ran great, even a little more power than the 1y engine.

Only thing is I now timed it by ear, because my timing gauge doesn't fit (m8 for IDI and m10 for TDI I think?). Also it sounds like the advance curve isn't exactly right. At idle it sounds allright, but at about 1500 rpm and about 2500 rpm it is a bit loud, as if it is running too advanced. Would placing the thicker tdi advance spring solve this?

Also, what would be a good figure to set the timing at? I read 1,3mm and that you should move the pump to the most advanced position to get to this number, but when I did that it sounded way too advanced from idle to 3000rpm. I'll probably modify my timing gauge to fit the TDI tonight, so it would be nice to have an idea of where about to set the basic timing.

-

#18

by

vanbcguy

on 14 May, 2014 08:54

-

It'll be hard to time "by the numbers" since you have a do it yourself pump. You'll basically have to adjust till it sounds / acts right.

There are a lot of variables in the dynamic timing system. There is the case pressure regulator, the spring and whatever shims may be there. Adding shims will cause the advance curve to start later. A stiffer spring will make the curve come on slower. Heck even the timing cap is a variable as it determines the maximum deflection of the timing piston.

Sent from my HTC One XL using Tapatalk

-

#19

by

SDTS

on 16 May, 2014 12:28

-

I think I have got it close to perfect, tried some combinations of static advance and advance springs, caps and shims, and now it drives perfect. Only thing is somewhere along the testing and adjusting it suddenly does't return to idle like it used to, the rpm drops quickly to 1500 and from there it slowly drops to 900, instead of going straight to 900 like it used to. I can't imagine I disrupted something by just changing the timing springs, so could this have anything to do with timing, or could something be broken inside the pump?

-

#20

by

SDTS

on 20 May, 2014 17:39

-

I have driven the car for about 600km the last few days without any problems, very satisfied with power and economy, but today something strange happened. I was driving home from work, 100km/h at 2500 rpm constant, and suddenly the car started to accelerate, so I depressed the clutch and rpm got to 3000 and stayed there. So I got off at the next exit, to see what was going on, couldn't see anything (it was dark, so I couldn't really have a good look), trottle lever works fine, so I backed out the fuel screw 1 turn, this got the idle down to 1000rpm. I got home, but the engine lacks power this way. When I shut the engine off, it kept running at about 200rpm, so I had to shut it down by letting the clutch go.

So tomorrow I'll have to see what is wrong, but where do I start? Could some spring or something have come loose, or something stuck in the governor?

Also the last few days the idle kept climbing to 1000rpm, every day I reset it to 800 using the idle screw, I think this also has something to do with it.

-

#21

by

8v-of-fury!

on 20 May, 2014 17:56

-

Interesting problem.. The fact that it ran fan, and then all of the sudden had a idle hang issue. Very weird.

Just a little tip however, had that of been an oil caused run-away pushing the clutch in would have allowed it to red-line and likely blow up. Never push the clutch in when the engine is running away, ever.. Disastrous results may follow.

-

#22

by

SDTS

on 20 May, 2014 18:44

-

Just a little tip however, had that of been an oil caused run-away pushing the clutch in would have allowed it to red-line and likely blow up. Never push the clutch in when the engine is running away, ever.. Disastrous results may follow.

Yes I thought of that before pushing in the clutch, but it wasn't accelerating very fast and still had some throttle response, so if rpm's would rise too much i figured I could let the clutch out again. If it started to run away, it would probably be time for a new engine anyway, so I could just as well let it happen if that was the case. Over here tdi's are very easy to find and very cheap compared to north america. I bought mine for 200 euros, including transmission, wiring, turbo and everything else.

-

#23

by

8v-of-fury!

on 20 May, 2014 19:29

-

I got a whole donor car running and driving for 275 Euro

Canada is the same way as Europe though for VW diesel stuff.

-

#24

by

SDTS

on 25 Jun, 2014 11:33

-

So I got the pump working perfectly and have been driving the m-sdi for 3000km now getting a constant 50mpg. But there is still one thing I would like to improve. The idle on my previous diesels felt much stronger, you could drive away just using the clutch and not touching the throttle. On this engine the idle feels more like a gasser and with every increase in load the idle drops, so the fan starting, switching the light on, or even the power steering drops the idle down quite a bit. Is there something I can adjust to get the idle to feel stonger? I have read a lot using the search on this forum, but couldn't find any way to make the idle more stable.

-

#25

by

Dino

on 04 Aug, 2019 15:53

-

Hello.

What's the news?

Do you the codes of the 8mm mechanical pump and of the 10mm electronic pump?

Is it possible to make the engine to run on a frunkenpump without levers cutting,drilling and welding?

Standard parts only.

The same power of a 1Y engine for a NA DI is enough for me too.

Thank you.

-

#26

by

ORCoaster

on 06 Aug, 2019 20:27

-

SDTS, Sounds like you are right on the edge of the fuel screw keeping the engine running. Try turning it in by a 1/4 or 1/8 of a turn. Should increase the idle a very little. But more importantly it will get you that tiny bit of fuel earlier when you are playing the clutch or adding an electric load.

If that gets the idle up too high for you, like 1050 RPM then turn the idle adjustment screw on the back of the throttle arm to a setting that is more to your liking.

Canada is the same way as Europe though for VW diesel stuff.

Canada is the same way as Europe though for VW diesel stuff.