AAZ rebuild (broke down in Maine) - page 3 - IDI Engine - VWDiesel.net The IDI, TDI, and mTDI source.

-

#30 by RockOcean on 04 Sep, 2012 15:44

-

Found intermediate shaft bearings here: http://www.rockauto.com/dbphp/prt,116,SH1209S

-

#31 by RockOcean on 04 Sep, 2012 19:10

-

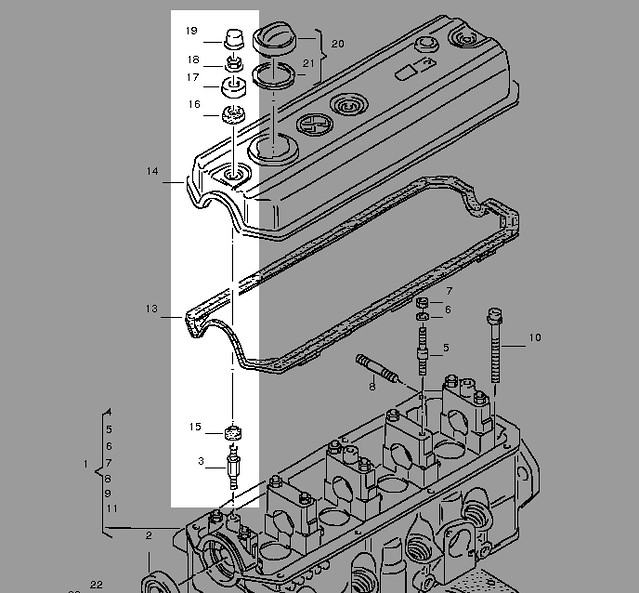

I have a valve cover coming but am gonna need these to put it on. Doe anybody have these for sale?

ValveCoverBolts (1) (1) by RockOcean.com, on Flickr

ValveCoverBolts (1) (1) by RockOcean.com, on Flickr

> 028103534A

> cover cap

>

> N 90132603

> hex. nut with washer

> M6 /

>

> 028103536

> concave washer

>

> 028103533

> sealing washer

>

> 028103532A

> sealing ferrule

>

> 028103531B

> stud / also use:

> M6X12 028 103 534 A -

#32 by RockOcean on 12 Sep, 2012 23:32

-

Been almost a week since my last post - waiting on parts. Then finding out I need more parts - then waiting on more parts. So here is what I got so far:

Finally fixed the odometer in the best way I thought - will have to see how long this lasts OdometerFixxWEB by RockOcean.com, on Flickr

OdometerFixxWEB by RockOcean.com, on Flickr

The cheap looking but supposedly better rear main seal SABOemail by RockOcean.com, on Flickr

SABOemail by RockOcean.com, on Flickr

Ahhh the neu 1.9L AAZ head this thing is beautiful IMG_0181 by RockOcean.com, on Flickr

IMG_0181 by RockOcean.com, on Flickr IMG_0195 by RockOcean.com, on Flickr

IMG_0195 by RockOcean.com, on Flickr IMG_0201 by RockOcean.com, on Flickr

IMG_0201 by RockOcean.com, on Flickr IMG_0207 by RockOcean.com, on Flickr

IMG_0207 by RockOcean.com, on Flickr IMG_0224 by RockOcean.com, on Flickr

IMG_0224 by RockOcean.com, on Flickr

Funny my second VW was this Porsche Mint Green color, I want to paint the block this color IMG_0243 by RockOcean.com, on Flickr

IMG_0243 by RockOcean.com, on Flickr

Freshly cleaned engine bay, its great when you can sit in it IMG_9912 by RockOcean.com, on Flickr

IMG_9912 by RockOcean.com, on Flickr

Neu hood ornament IMG_0434 by RockOcean.com, on Flickr

IMG_0434 by RockOcean.com, on Flickr

Here is my custom oil filler/checker IMG_0461 by RockOcean.com, on Flickr

IMG_0461 by RockOcean.com, on Flickr

The neu cap didn't have a hole in it for a dip stick since it was only designed as a filler. And my old cap would not fit the neu filler tube due to slightly diffrent threads. Also I needed a more flexible dipstick that would make the bends needed to reach the oil level. IMG_0454 by RockOcean.com, on Flickr

IMG_0454 by RockOcean.com, on Flickr

So I ended up drilling the centre out of the old cap and then drilling a small hole into the neu one and glued the old piece on to it. O yeah I had to turn down the top of the neu cap to make it flat. IMG_0451 by RockOcean.com, on Flickr

IMG_0451 by RockOcean.com, on Flickr IMG_0445 by RockOcean.com, on Flickr

IMG_0445 by RockOcean.com, on Flickr

I then put bigger o-rings on the custom VR6 dipstick so that it would have a snug fit. You can get these dipsticks from my brothers shop. IMG_0472 by RockOcean.com, on Flickr

IMG_0472 by RockOcean.com, on Flickr IMG_0540 by RockOcean.com, on Flickr

IMG_0540 by RockOcean.com, on Flickr

I should be getting the block back from the shop tomorrow and the injectors any day now. -

#33 by Syncroincity on 14 Sep, 2012 05:02

-

IT'S SO SHINY I'M GONNA DIE!

Great progress and pics, keep 'em coming! I love the oil dipstick, very creative. -

#34 by starrd on 14 Sep, 2012 10:59

-

When you install that rear seal - REMEMBER

-no lube

-install and let sit over night prior to rotating the crank so it expands and sets to the crank seal surface

Otherwise it will leak -

#35 by burn_your_money on 14 Sep, 2012 13:05

-

Is that head from Giles?

Hopefully the parts arrive soon! -

#36 by RockOcean on 14 Sep, 2012 14:14

-

Thanks

First problem has arrived: After torquing down the main caps it wouldn't turn freely so I loosened caps 1 and 2 - turns freely. But when I torque cap 2 it doesn't move freely. Only with all torqued and cap 2 loose does it spin freely. Any ideas? Everything looks good -

#37 by libbydiesel on 14 Sep, 2012 15:09

-

The caps in the right places?

Otherwise, pull the crank, measure the hole when #2 is torqued. Measure #2 crank journal. Within spec? -

#38 by RockOcean on 14 Sep, 2012 18:46

-

Yes the caps are in the right place and orientation, will check those measurements tomorrow. Thanks

-

#39 by libbydiesel on 14 Sep, 2012 19:31

-

For the dipstick, measuring at the block port with the 83+ dispstick/tube style I showed earlier is much more accurate. Measuring at the extreme rear corner of the pan means that any slight variation in levelness causing a significant change in the reading. That's why I recommended going with the later style.

To keep the odo gear in place I have pulled the gear off, put some dimples in the shaft using pliers and then superglued it back in place. I'm afraid that the added screw will shred the gear long term. -

#40 by RockOcean on 14 Sep, 2012 23:17

-

I would have done the 83+ dipstick mod but my funds are very low and I already ordered the new style oil filler. I actually carry a full size level in my van and always check to make sure the van is level when I check the oil.

I found the reason to my crank not turning freely was due to the wrong or un level bolts. The bolts that were in it originally were the fully threaded newer style bolts and the new ones I got for it where the older style half thread. There is a guy down the street that owns a operates a machine shop mostly rebuilding air cooled motor. His shop is amazing and his workmanship world class, so I told him my problem and he said to leave it and he would come down later to check it out.

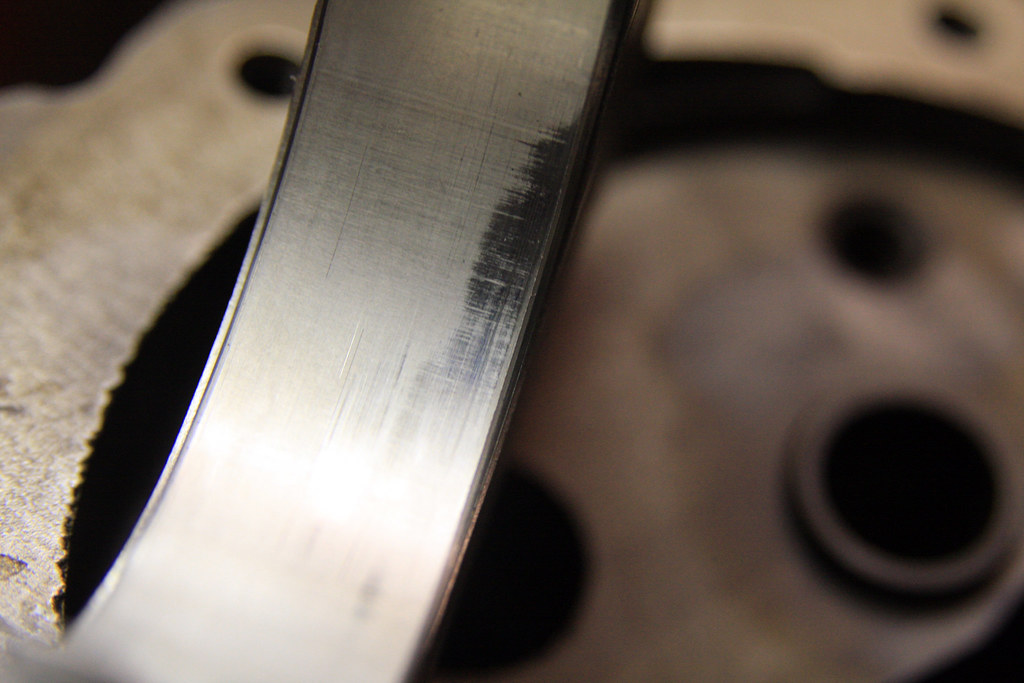

We put a dial indicator on the crank journal (I may be using the wrong term here) and the crank was spot on. He them said to torque it down and turned it even tho it was jamming just so he could see what kind of mark it would make on the bearing. Sure enough it left a wear mark on the bearing. After a bit of thinking he then questioned the bolts, so we torqued down the original bolts. With the original bolts it spun almost as it should but still had a little deviation at a certain point. So then he suggested using "emery cloth" to clean the inside of the cap. Sure enough after that it was spinning freely.

My concerns are with this little bit of wear on the bearing should I change them? And should I reuse the bolts? I am a do what ever the Bentley says type of person and they say not to re use them. But does it really matter? Thanks guys I really appreciate this forum and all of your input.

Here are some photos of course:

I take it that I am going to need to clean the paint off where the gaskets go? IMG_0573 by RockOcean.com, on Flickr

IMG_0573 by RockOcean.com, on Flickr

The re bore looking nice - as far as I know. IMG_0582 by RockOcean.com, on Flickr

IMG_0582 by RockOcean.com, on Flickr IMG_0586 by RockOcean.com, on Flickr

IMG_0586 by RockOcean.com, on Flickr

Prothe Pistons with Grant Rings - so much fun filing these rings down to spec. ha IMG_0604 by RockOcean.com, on Flickr

IMG_0604 by RockOcean.com, on Flickr

Its always gotta be something when working on an engine this time it's that damn #2 cap IMG_0608 by RockOcean.com, on Flickr

IMG_0608 by RockOcean.com, on Flickr

Here are the wear marks that it made when turned with the new bolts torqued down. IMG_0614 by RockOcean.com, on Flickr

IMG_0614 by RockOcean.com, on Flickr

These are the bolts, the ones that were in it the newer style on the left and the never used before older style on the right that binded up the crank. IMG_0638 by RockOcean.com, on Flickr

IMG_0638 by RockOcean.com, on Flickr

-

#41 by RockOcean on 14 Sep, 2012 23:26

-

No Giles did not want to sell me his cam with the head. So when I found out my cam was no good I decided to order a complete head from here: http://shopping.boraparts.com/product_reviews.php?manufacturers_id=32&products_id=32

But I did get my injectors back from him yesterday :- ) -

#42 by CrazyAndy on 15 Sep, 2012 10:35

-

Gee Rock, if you had only let me know that a Cam was all that held you back on Giles' head I would have offered my used one along w/ my VC. Hopefully getting a complete head from Smokey Eddie soon so i con't need it. Buy ey, that head looks too damn beautiful to pass it up!

I'd clean off some of the paint on the gasket mating surfaces, or at least smooth with finishing sandpaper discs for a smooth surface. -

#43 by RockOcean on 16 Sep, 2012 11:30

-

Is there a definitive answer for replacing the main cap bolts? The Bentley says you don't have to so I assume that is right? Right?

-

#44 by burn_your_money on 16 Sep, 2012 11:39

-

I have seen at least 2 AAZs that blew apart because bolts weren't replaced that should have been. Like rod out the block blown apart. I wouldn't chance it. Guilianot is one. Although, his might have been rod bolts...

Definitely mains

http://www.vwdiesel.net/forum/index.php?topic=10690.60