Cross-posted from Vortex as the diesel forum there is d.e.d. dead. And ya'll may get more entertainment out of it here.

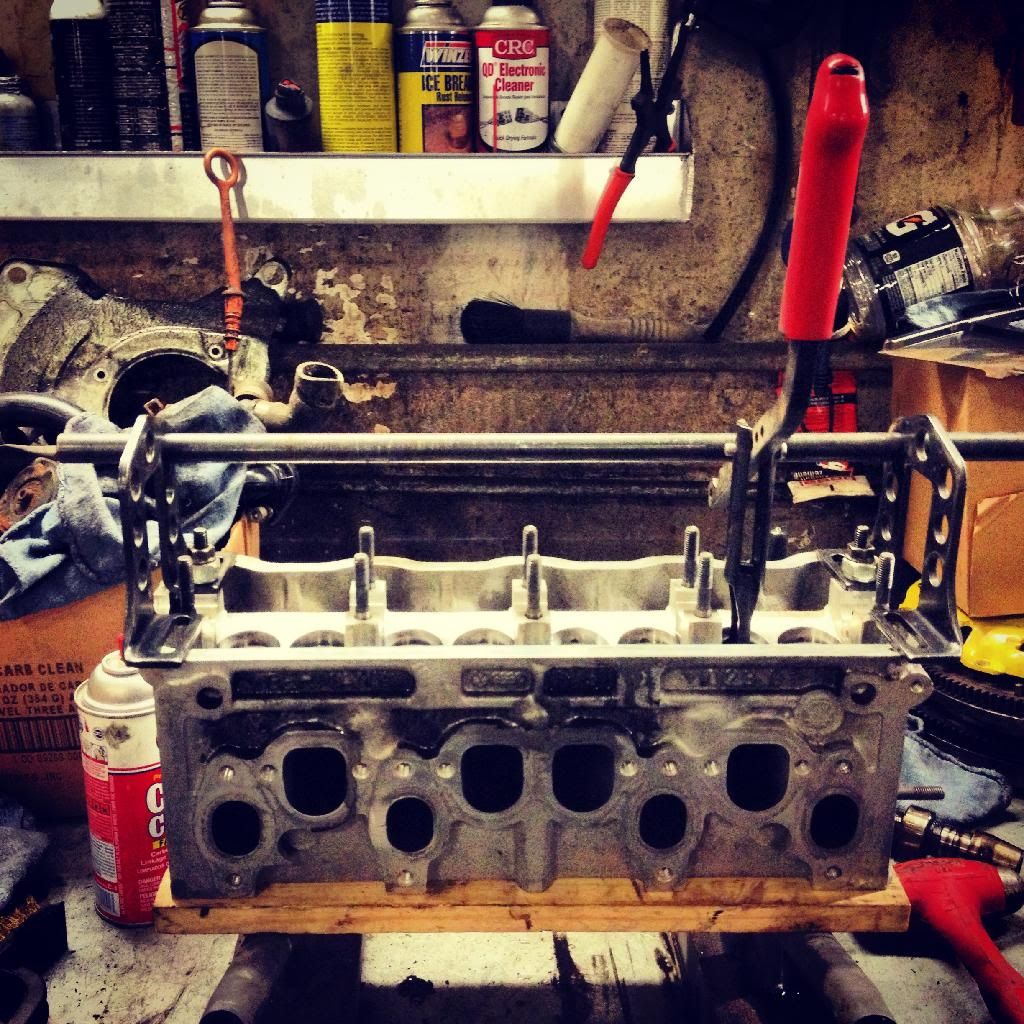

Recently acquired a rust free '98 Jetta from a friend when it dropped a valve on the highway. Found a cheap extremely low mile '98 TDI complete motor (<100K mi.) the motor was in really poor cosmetic condition so I stripped it down, then painted and resealed the whole motor. Added a factory ABA windage tray/oil pan gasket.

I hadn't originally intended on hot-rodding this, but it's got a slightly larger than factory turbo, chip and a bunch of other work, so while I have the head off, I'm going to work my port magic on it. I've also had some lengthy and beneficial discussions with a local fellow that races a 1.6TD. He's seen incredible gains with minimal port work so the length I'm going to should be....interesting... And before you go saying I shouldn't, know this isn't my first rodeo. I have considerable experience with porting heads and am confident even with a factory sized turbo I should see decent gains from my time spent here. The factory casting and ports are absolutely horrendous. It's almost embarrassing. Especially the exhausts. Ugh!

At any rate:

Incredibly clean, makes the mileage believable

Removing valves, wood block bolted with old head bolts to keep valves from opening. a bunch of the keepers were "stuck".

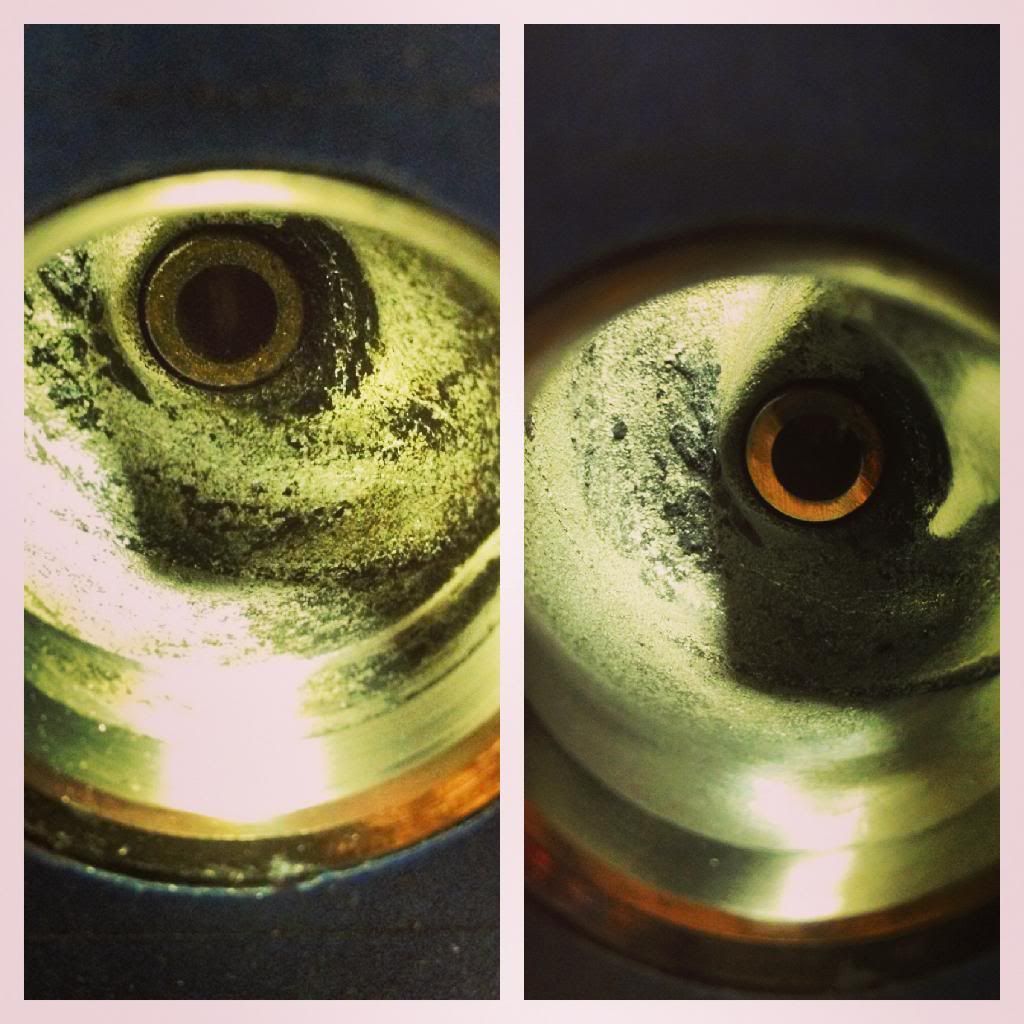

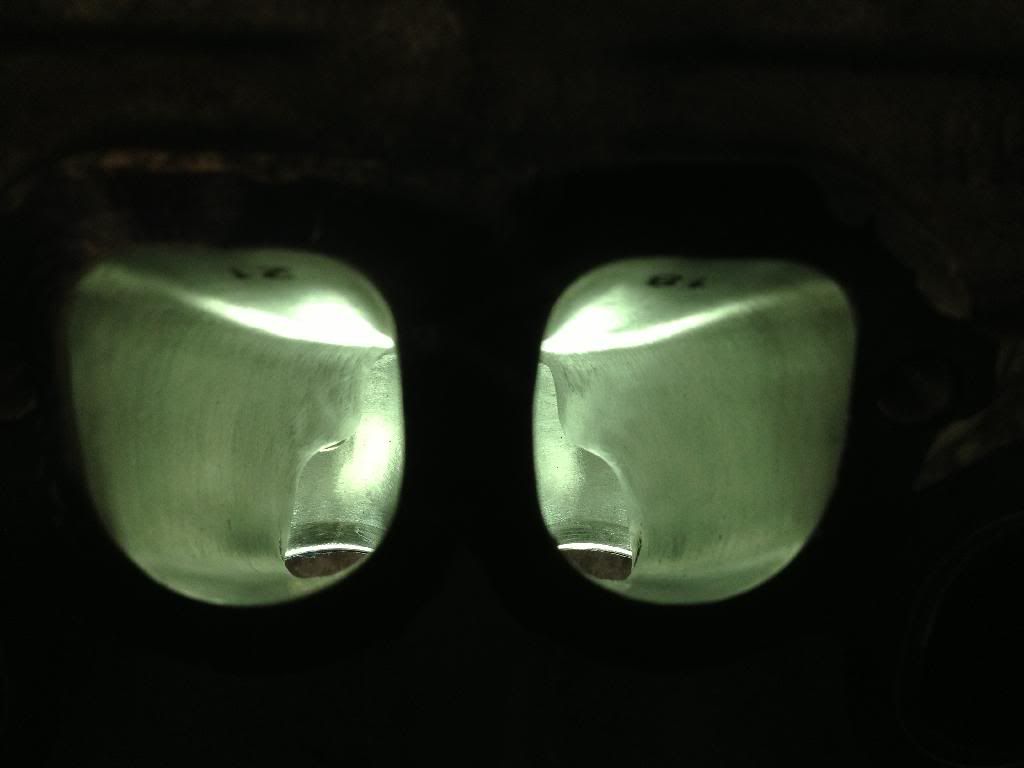

Some substantial work is going into these exhaust ports. And this is just a gasket-match. The throats and short-side radii are awful.

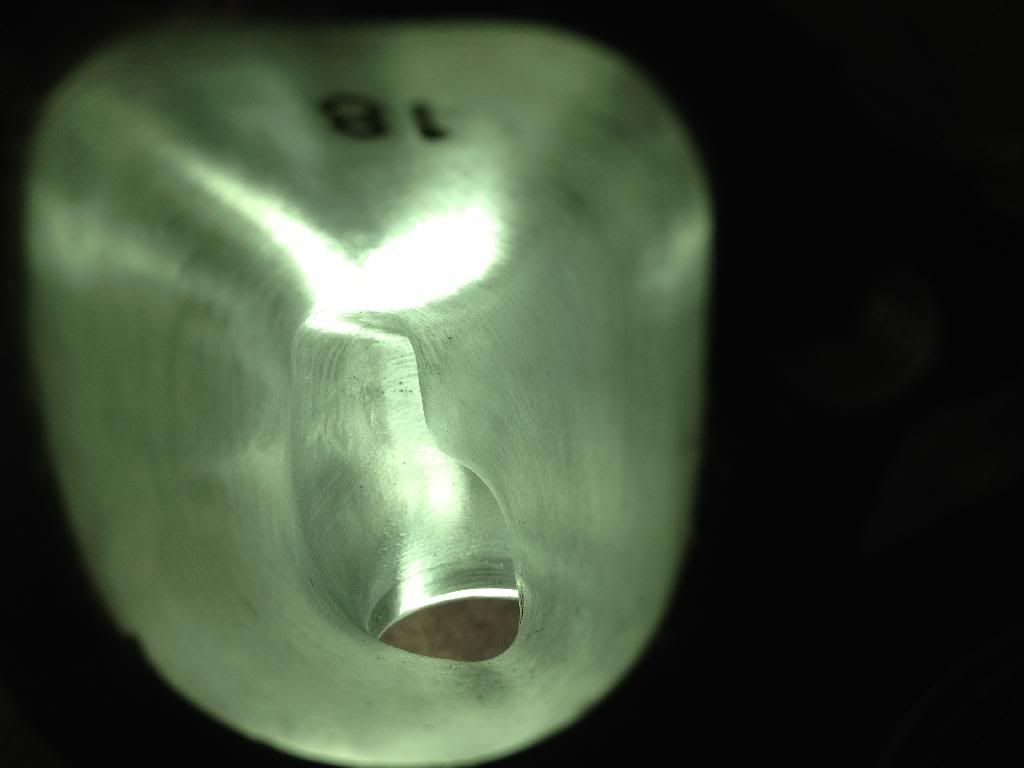

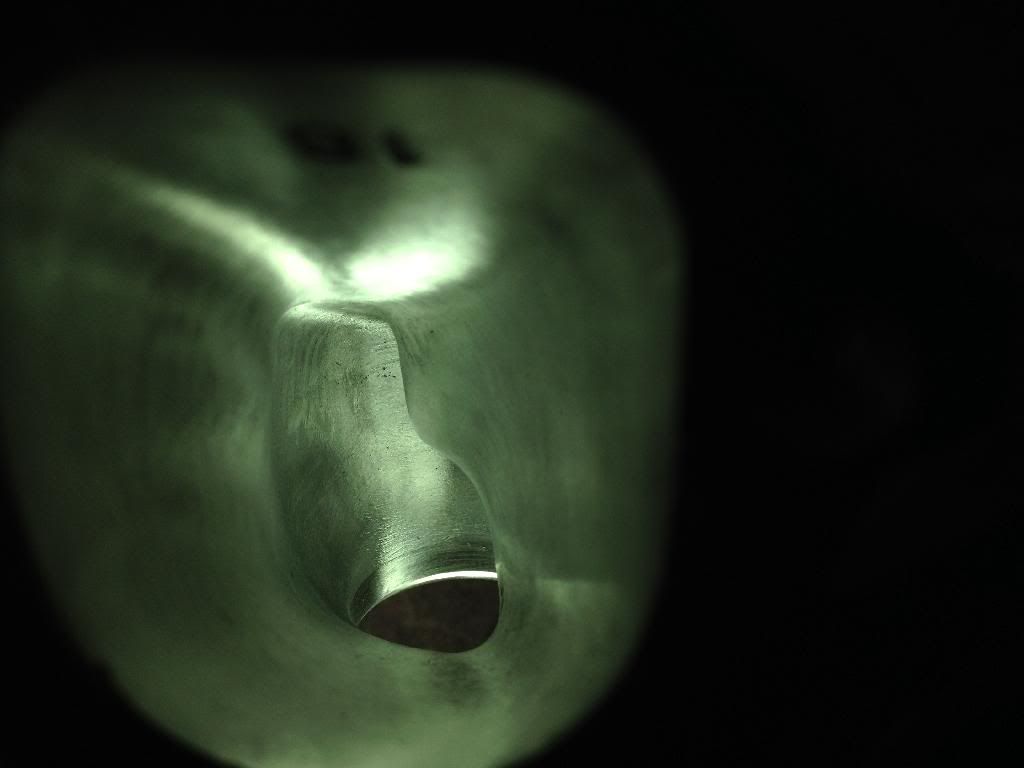

Intake port "ridge" on left and knocked down on the right.

Another angle on the "ridge" ( at 6 o-clock) from where they bored the hole for the valve seats.

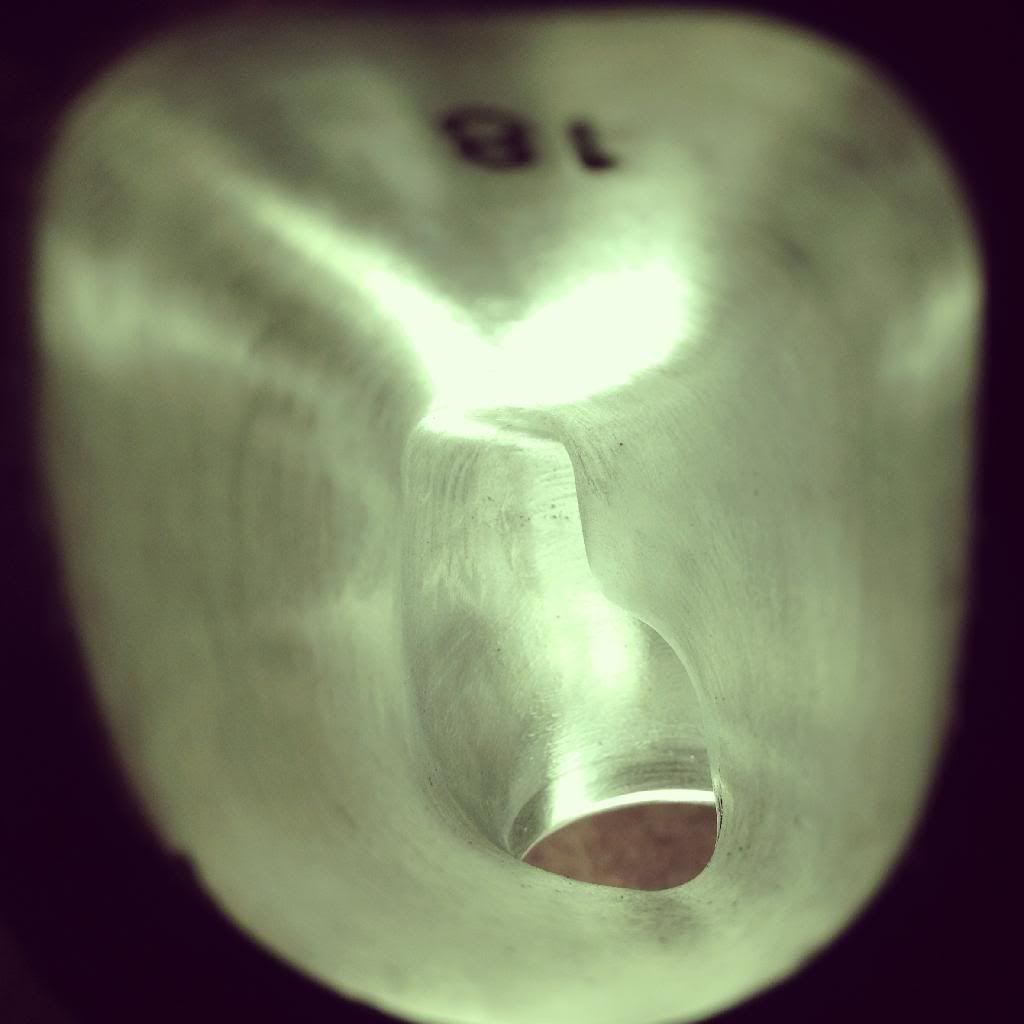

Same port with the ridge knocked off and blended into the bowl

Working the bowl.

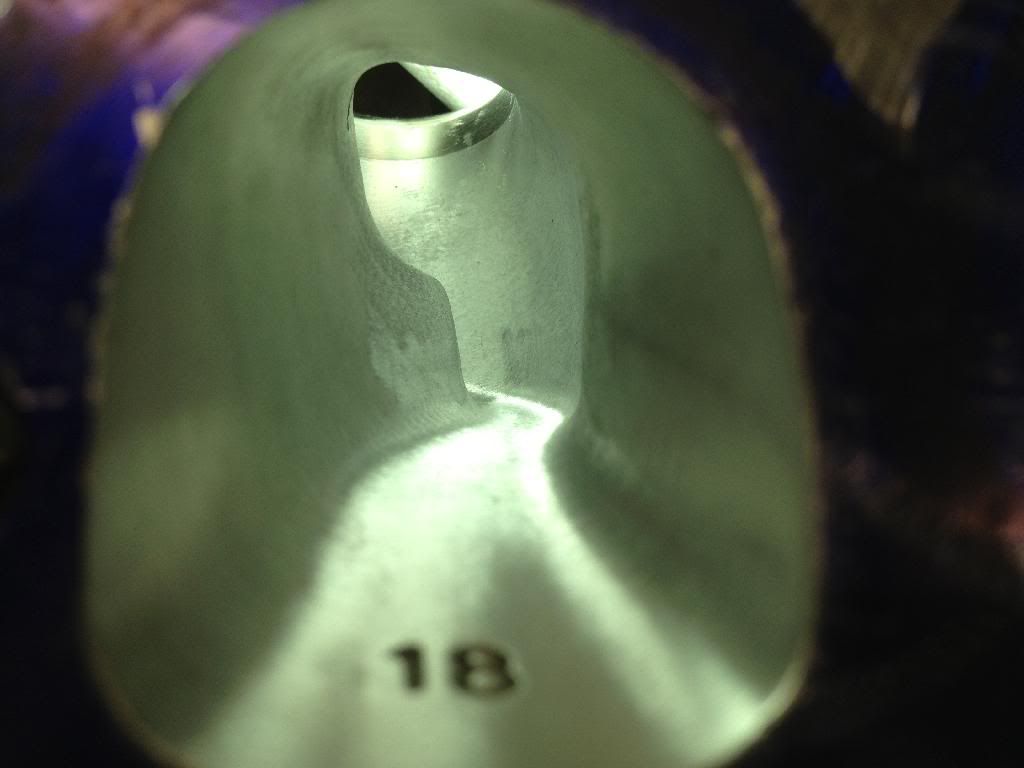

Unique swirling bowl shape compared to the gas motors I'm used to porting.

After some hours you get a nice smooth 120Grit finish on the ports

The narrow valley is rather difficult to get a nice smooth finish on, I may go back with some 240 once I get more narrow bits.

Intake ports needed no port matching, they are almost exactly the size of a factory metal gasket. So no enlargement of the ports was performed, just bowl, short side radii and polishing.

The exhaust ports however. *sigh*

Roughing the exhaust ports in to just under the final port size with an aluminum specific carbide at low rpm. Not worried about going into a water jacket, the metal is pretty beefy in the outer area. port match blended back into the throat to just before the valve guide boss.

Jeweled

My eyes need a break. 6 hours is enough for one day.

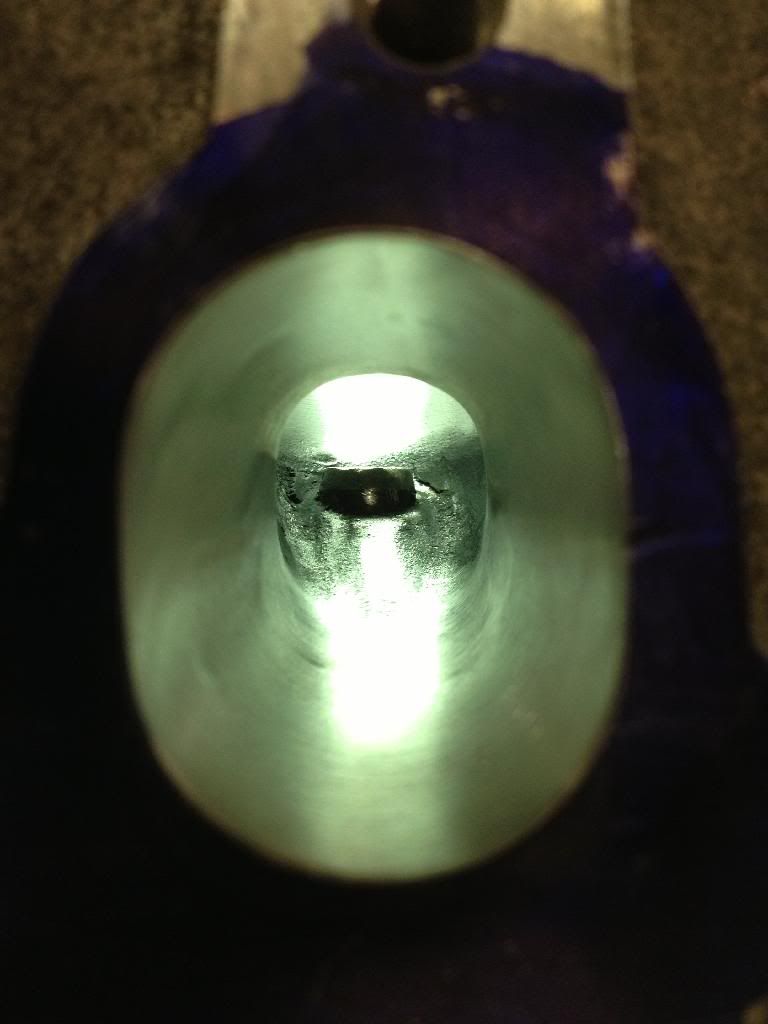

Finished up the exhaust ports. Didn't take the short side radii down as much as I'd like, but seeing as I'm not exactly sure how thick that area is I went as far as I was comfortable. The rough "jewel" finish is taken down with 60 grit cartridge rolls, finer tuned with 80, then 120, 240 and lubricated cross-buffs.

80 grit stage, working out the remainder of the rough-in marks. Can still some remaining carbon and the rough finish up by the guide boss.

Final finish ends up like this:

I'm not very concerned that the exhaust isn't completely "neat" being that it's already such a vast improvement over what it was stock. If I were replacing the guides i would have taken them out and done some finer finish work around the boss area.

Wasn't satisfied with the final finish on the intakes. Went back and finessed them a little bit.

Overall, pretty pleased with how it came out.

Next up, matching the turbo manifold to head, and turbo to manifold....